Light commercial vehicle manufacturers frequently stress that most of the vehicles rolling off their production lines undergo some sort of conversion before being delivered to the end user, whether this be the fitting of a tipper, dropside or box body to a 3.5t chassis platform or the installation of racking inside a compact van.

The shift towards electric vans has necessitated changes for bodybuilders – primarily with the need to use lightweight materials to offset the weight of the batteries, which would otherwise eat into payload capacity.

Maxi-Low has been building specialist lightweight low floor bodies for many years. In 2024, it developed what it claims is the UK’s first low floor electric urban delivery chassis, capable of carrying more than one tonne in payload.

Maxi-Low says its ultra-lightweight vehicle is nevertheless sufficiently durable to meet the rigours of everyday operations. The polypropylene body is 95% recyclable and tough enough to withstand a 1.2 tonne side impact to the panels. It also features an anti-slash roof for added security in case thieves try to cut into the load area from above.

Maxi-Low says the body is constructed in such a way that it can be repaired without completely replacing panels, which minimises downtime if damage does need to be made good.

Features designed to make the working environment as safe and easy to use as possible include lowered entry access and positioned access points. The lightweight body is the first in a range of electric urban delivery models Maxi-Low will develop during 2025 as it moves towards building more than half of its bodies on electric platforms.

As its name would suggest, CoolKit is in the business of supplying fridge freezer conversions. A recent innovation is the firm’s CurtAir air curtain option, which food wholesaler and longstanding customer Total Foodservice Solutions now considers standard requirement.

The air curtain in CoolKit’s refrigerated vans offers benefits including improved access for operators due to unobstructed entry and exit, which is particularly useful during multi-drop delivery work. It saves time, reduces effort, and enhances health and safety by providing clear visibility. Additionally, the air curtain effectively maintains internal temperature, preserving perishable goods and reducing strain on the refrigeration system thus leading to lower energy consumption. It also helps maintain hygiene by keeping out dust, dirt and insects.

Endorsing the product, Mark Thornton, Total Foodservice Solutions transport and distribution manager, says: “We had always relied on PVC strip curtains as temperature control is paramount but our experience with the air curtain has been nothing but positive, so we spec these on every vehicle now.”

A mark of CoolKit’s success is that, in quick succession, it has recently been awarded preferred partner status by both Mercedes-Benz and MAN.

Converters keeping loads cold in transit do not have a monopoly when it comes to innovation, however. Working in partnership with Monmouthshire County Council, Vantastec has developed a meals-on-wheels van that uses hydrogen to power its microwaves, regeneration ovens and water heaters. Based on a Nissan Townstar EV, hydrogen drives its onboard equipment too.

Vantastec is in the process of patenting its hydrogen unit, which can be refuelled in under 10 minutes and can be used as a standalone power source for charging a battery-powered van.

Inside job

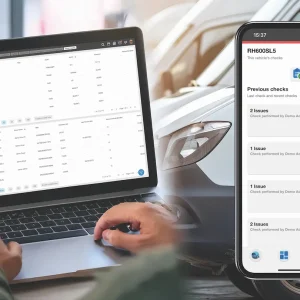

Perhaps better known for making pipe and ladder-carrying equipment, Rhino Products has launched a load area racking system (pictured), which it says is durable and lightweight and suitable for both electric and ICE vans. Using Rhino’s new configurator, MR4’s modular design enables van operators to specify racking to meet their individual needs.

Each racking unit is made to measure to maximise the storage potential of the cargo area and options include aluminium drawers, drop fronts, lockers and work benches.

Thanks to Rhino’s no-drilling flooring partnership with Legend Fleet Solutions, drilling is not required to install MR4. Rhino points out drilling can damage a van, affecting its resale value and can also invalidate the vehicle manufacturer’s body and paintwork warranty.

Rhino also offers an ‘express’ MR4 range, whereby it keeps the most-popular configurations in stock and flat-packed ready for same-day dispatch